Oct 30, 2025

In the flexographic printing technology system, the flexo plate making machine is a key piece of equipment that determines printing quality, efficiency, and cost. With the increasing demands for precision, environmental friendliness, and production cycle time in the packaging, labeling, and publishing printing industries, flexographic plate-making machines have gradually upgraded from traditional manually operated equipment to high-end industrial equipment integrating automation, digitalization, and intelligent technologies.

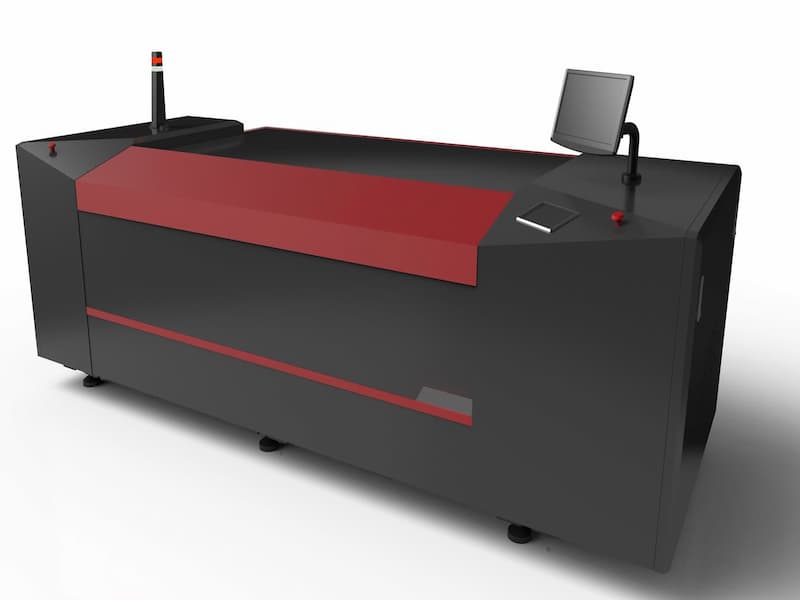

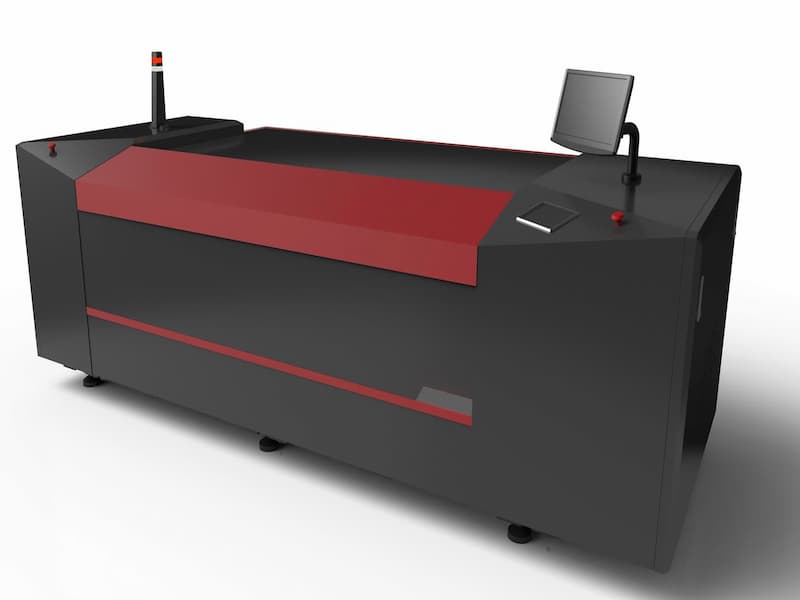

As a "bridge" connecting design and printing, our company can provide complete sets of equipment, such as Flexo CTP machines, flexo plate exposure machines, flexo plate washing machines, and flexo plate drying & UV light treatment machines.

The functi...

Read More